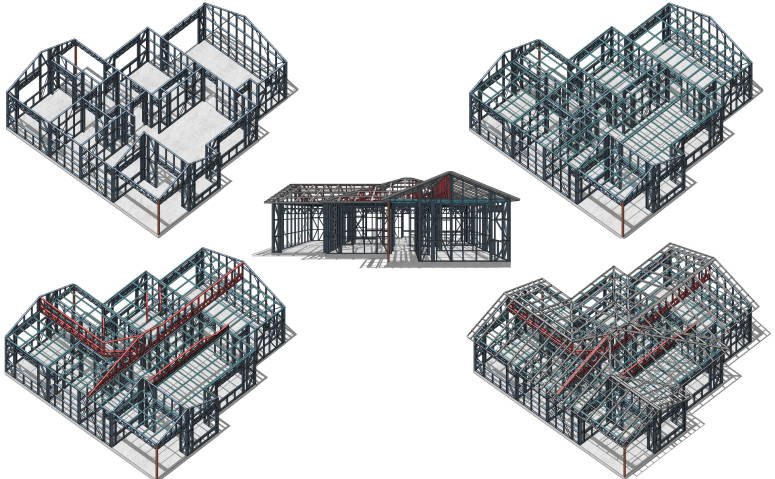

Engineering design S/W and roll forming machines are developed and manufactured by same company who have pioneered in steel frame & truss manufacturing technology. Software & machines are seamlessly integrated avoiding unwanted non compatible issues and maintaining highest quality standards. This intuitive design S/W reduces multi-step processes into a single integrated solution that seamlessly integrate with roll farming machine.

Partner with Us

Reliable & Quality-Oriented

Advanced Design & Engineering Process

Consistent Un-Compromised Quality

When you work with Steel Frame Australia, you know you are dealing with reliable & quality-oriented experts in the building industry. Our advanced design, engineering and fabrication process and high-quality materials we use are second to none, so you get timely product every time with consistent un-compromised quality allowing you to complete your project efficiently & economically.

Strategic Advantages:

Full Package:

Inbuild Intelligent:

Engineering design software is perhaps the only industry system that combines engineering and design for a complete solution.

Fully AS Code Complaint:

Innovative Tailored Design:

Every project is unique so every framing solution should also be unique. We offer best possible solution to our clients be it truss fabrication, panel fabrication or hybrid fabrication system. We work closely with our clients.

State-of-the-Art Roll forming Machines:

Point of Differences:

Quality:

Once we pick up a project, a project schedule is put together and shared with our clients. Every milestone is tracked and monitored. Every phase of the project goes through rigorous quality checks to achieve highest quality. The product is precise & durable without any defects that allowing faster and easy installation and avoiding unnecessary project delays.

Near Real Time Tracking:

Our e-commerce platform allows us to provide new real time status update to our clients. As the project goes through different phases, our Clients get email and mobile notification. Once we commence the project, a detailed project schedule and delivery ETA is shared with Customer. Our Customer can also login to their account online to track progress and other information. In brief, we keep our customers engaged during the project journey and time to time, our team also provide brief updates via phone calls or other preferred methods of contacts.

Continuous Improvement:

We thrive for continuous improvements as we truly believe excellence is a continuous process and biggest room in the world in room for improvement. We retrospect our projects for learnings and improvements. The biggest source of improvements are our Clients and we always seek feedback and suggestions. Rather sitting in office, we often go to site (with Client’s permission in place) to gather real feedback and ideas.

Short Lead Time & On-Time Delivery:

We maintain high professional integrity & ethics. We understand the importance of meeting delivery timelines with consistent quality. Once we take on a project and commit to delivery date, we deliver. We do not promise, we commit to it.

Design & Engineered by Experienced Designers:

Design & Engineered by Professionals & Trained Designers:

Our designers are highly skilled and have undergone rigorous engineering design S/W training. The designs produced by our designs are second to none in terms of quality & practicality. Attention to details not only covers location of solar panels , skylights & air conditioning unit locations but also for future furnish work such as pendants, chandlers & TV locations for load distribution so our engineered designs are practical for future piece of mind for our Customers.

B2B Studs & Rafters

Strap Bracing

Windows & Doors Opening

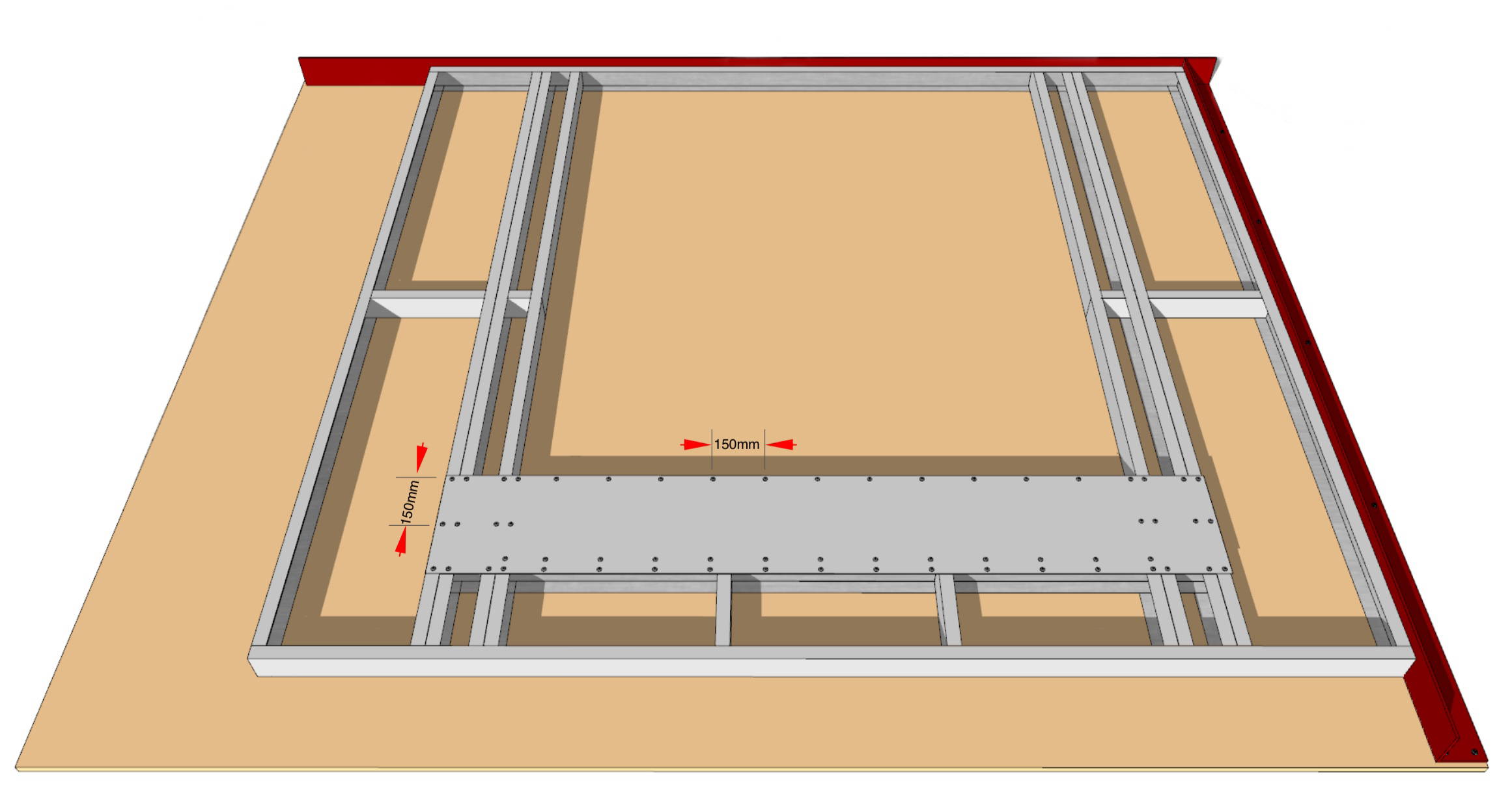

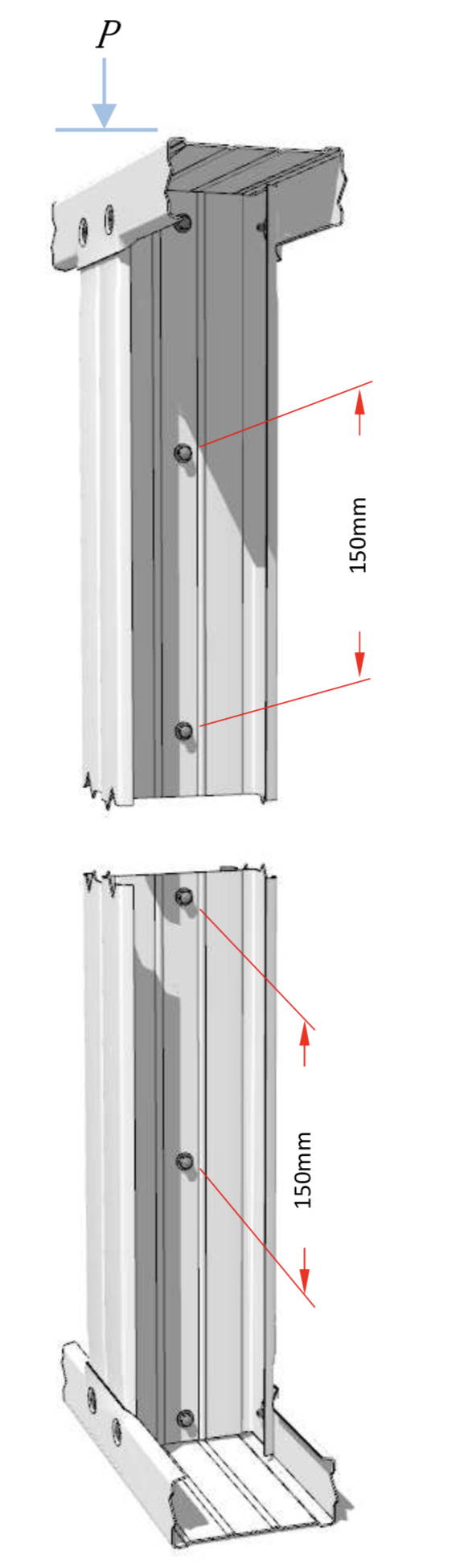

* Lintels for all openings are stitched (plated) with screws at 150mm centres around the perimeter. Any vertical stud member passes under the plate are screwed to the plate to transfer load down to the stud to the foundation.

** All jack studs are screwed to jam stud to allow transfer load from bottom chord lintel into jack then into jam stud.

*** For double chord lintel, both chords are screwed together for improved load distribution.